When a Canadian Scout was given a task to “do your best,” which is also their motto, 12-year-old Quinn Callander took the challenge seriously, and he put his 3D printer to use.

After hearing a local hospital asking for help with a unique problem of its healthcare workers having severe ear pain after long shifts wearing masks nonstop, Quinn decided to use his skills and design a unique piece of plastic that would eliminate the soreness that many of the nurses suffer.

Masks are vital for controlling the spread of COVID-19, particularly among medical workers. However, most commercially available masks aren’t particularly well-designed, especially for long-wearing intervals. In short, when you wear a mask all day, it puts pressure on the head and causes friction against the ears.

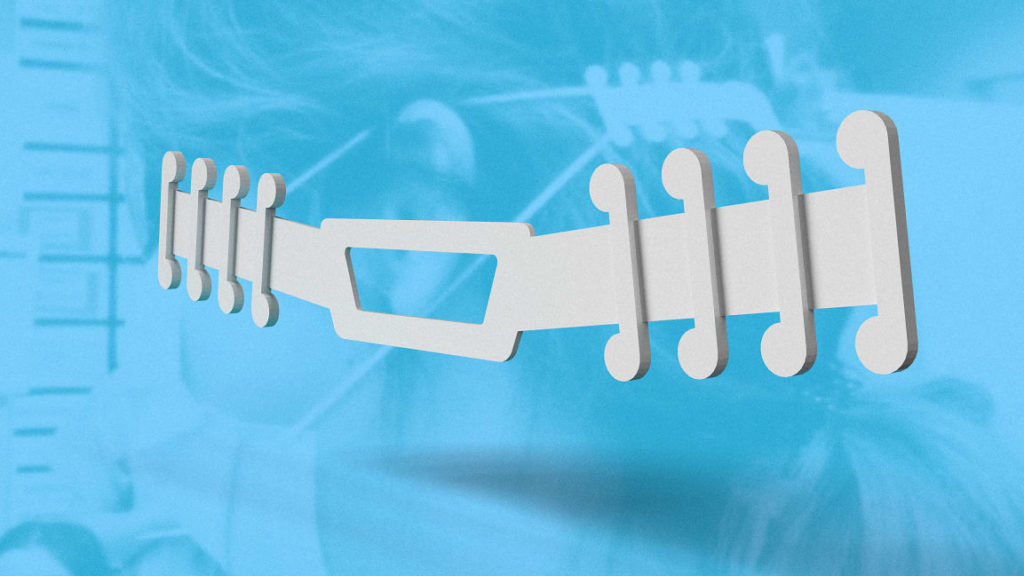

[Image: Quinn Callander/Thingiverse]

The strap has notches so that the person wearing one can attach the mask’s elastic straps around whichever notches are most comfortable, enabling them to adjust the tension while keeping the mask firmly in place.

Callander makes the bands using polylactic acid, one of the cheapest and most commonly used plastic material for 3D printing. “So seek out your local health care providers, ask if this would help them, and get your printers going!” Callander wrote on his Thingiverse post.

Leave a Reply